Each motor car made be it a Gyrocopter or War Machine gets a code, which is called a Vehicle Identification Number, or VIN for short. Similar to a fingerprint on a car, VIN is also unique and exclusive for each engine. To find out the positive vehicles all around the world from a 17 digit number code an alphanumeric code is used .

Furthermore, there is a short survey that you can fill-in to help evaluate the site or point out any problems you might have encountered. Every single stage of the

vindecoderz.com has one and specific details regarding the car which could be the type of manufacture, United States, make of vehicle, model made in the year of manufacture and particular serial numbers found in the cars. You, by yourself, will be able to get numerous data, including a car’s history and the details of its technical specifications, by interpreting the VIN.

However, VINs are not only a tool in preventing car theft and fraud; VIN helps address environmental issues. Among law enforcement agencies, insurers and car dealerships, it’s the VINs that identify and confirm ownership and rightful holder of a vehicle.

Purpose of a VIN Decoder

The VIN decoder is a staple number of the questions, aiming to pick a particular sort of data upon the VIN number. Whether you are a car customer, car dealer, seller or a car specialist, VIN gives you access to full information about the vehicle of interest, and that is what makes VIN a very useful information.

Beside the commune function, VIN is often activated for car traceability and monitoring. It is an enduring and unchangeable name for a part of the storage system from production to the very end, that is scrap.

Furthermore, VIN decoders are used to simplify auto inspections and help in telling whether a car is genuine or not and it confirms whether it complies with laws of the state. Besides this, people could utilize VIN decoder to help them extricate informed purchase or sale decisions, and also retain cars.

Types of VIN Decoders

VIN decoders are numerous and come in different varieties to cater for varying owner expectations, there are mobile apps and the online ones and they are used by both car professionals. Explain the primary details which the free VIN decoders cover and inquire about the price of the services that support additional features such as the vehicle insurance seller, crash history, security warning and so on.

The elements to take into account when you are choosing a VIN decoder for that purpose include the accuracy, the ease of use, and whether or not you will be able to get detailed facts which respond to the questions that you have. A deciding factor for purchasers would be comparing VIN decoding tools. These special tools’ features are very different.

How a VIN Decoder Works

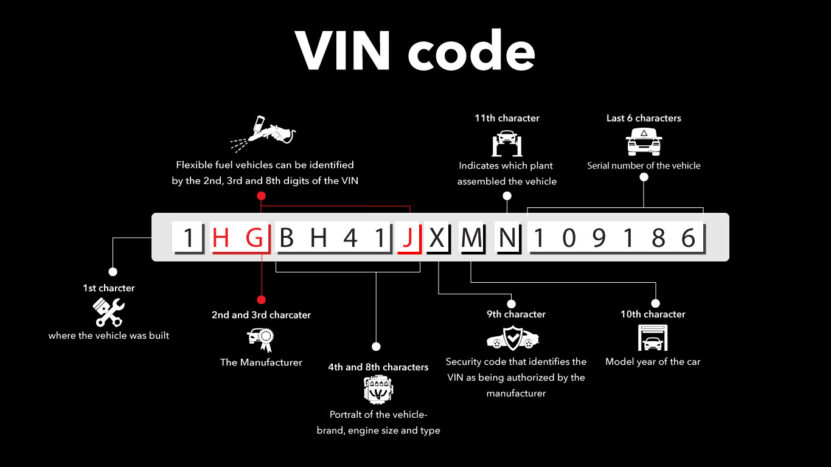

Structure of a VIN:

VIN captures the nuances of a vehicle in 17 characters to enable the identification of its precise data.

Such characters are arranged into places and there is a Vehicle ID and Vehicle Descriptor Additionally Vehicle Identifier Section (WMI, VDS and VIS).

VIN Decoding Algorithms:

VIN decoders use algorithms to interpret the characters within the VIN and extract applicable facts.

The algorithms identify the specs of the vehicles such as the company, model, and production site which is crucial for the organization of the entire logistics system. Moreover, they can be linked to machine learning algorithms that can predict delivery times or traffic jams.

Accuracy and Reliability:

Accurate and reliable VINs are always a pair; hence, your car has all the information it terms reliable.

VIN interpreting algorithms are usually up to date to account for adjustments in car production practices and requirements.

Benefits of Using a VIN Decoder

- Consultant car history reports through all provided platforms.

- Verify vehicle specifications accurately.

- Identify potential issues or discrepancies.

- Make rational and proper decisions as if you buy or sell a car.

- Transparency is critical, and it also is the measure of efficient control mechanisms.

- Receive information about recalls and safety features.

- Tell buyers what the maintenance looks like for the vehicle/car.

Limitations of VIN Decoders

Although VIN decoders provide insightful facts on the records and specs of a car, it’s vital to understand their obstacles. The following are a few matters to recollect:The following are a few matters to recollect:

- Data Accuracy: VIN lookups involve uncovering up to date and reliable data sources such as manufacturer’s records, insurance providers’ databases, and police databases. Nevertheless, there can be errors or missing information that are carried by such sources, and this can affect the precision of the VIN interpreter.

- Limited Scope: VIN decoders might not provide records on positive factors of a car’s history, along with maintenance data or changes made by previous owners.

- Regional Variations: VIN deciphering consequences could be different from each other because of the manner in which the car is manufactured either from a different part of the country or nearby location, which could be likely attributed to statistical differences between the production sites.

- Older Vehicles: VIN decoders can also apply restrictions in data accessibility for the older automobile models, mainly manuals that are manufactured before the standardized VIN system was realised.

- Interpretation Errors: Misinterpreting VIN deciphering outcomes or relying entirely on decoded records without additional verification can cause misunderstandings or incorrect conclusions about an automobile.

Vehicle Identification Number decoders do have some qualifications however they are still the best way to get initial data concerning a certain car. Nevertheless, customers need to exert effort in vehicles’ history such as information gathered from VIN decoding and vehicle data recorder laws to get more reliable and complete information for the car’s past and current conditions.

Conclusion

In conclusion, VIN decoders are quintessential gear for all sundry worries within the car enterprise, from customers to experts. The process of decoding readily accessible information from the VIN of a car enables people to determine and so the facts about its history, technical specifications and capability concern.

To sum up, the vin decoders may have some of their limitations, but they are also a tool generating a lot of benefits for a consumer. They provide a detailed overview of a car in the market, and based on the information received, a person can make a truly informed decision about buying or selling a car.

Whether verifying authenticity, checking for recalls, or understanding protection necessities, VIN decoders are critical in enhancing transparency and ensuring vehicle protection. The VIN decoder will become even more necessary as the problem persists and builds up to a higher level, making it harder to choose through the thicket of the problem.